| PROFESSIONAL

PILOT BOATS

WE ARE WORLD LEADERS IN PILOT BOATS, 20 VESSELS SUPPLIED TO PORTS WORLDWIDE IN THE LAST 6 YEARS CONSTRUCTION & STRENGTH

|

|||||

|

Our GRP hulls are

tremendously strong, GRP is an excellent construction medium. All our

vessels hull have full plan approval from either Lloyds or BV, and

scantling determination is carried out using Lloyds SSC software. We

only use single skin composite laminates, as for a pilot vessel the risk

of delaminating over the long lifespan of the vessel with cored

structures is to high, not to mention the difficulty in effecting a

repair years latter. We use high strength compisite laminates in a heavy

duty lay up, typically our pilot vessels will have a bottom laminate of

9,000gm2+ with keel laminates over 11,000gm2. In

addition to comply with Lloyds Part 8 3.6.5,

the side shell laminate is increased locally from the bow to just

aft of amidships where maximum beam occurs by 50% of the side shell

laminate down to the first longditudal stringer (500mm below the

sheerline). And the transom boundary is increased by 50% of the shell

laminate 1m f/wd and across the transom from the quarters down to the

chine.

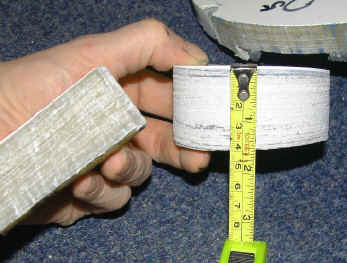

Below, typical cut outs showing how thick and correspondingly strong the GRP shell laminate is in paces.

Superiority

of

GRP over Aluminium

& Steel Hulls Strength-

comparing steel to GRP, weight for weight a modern GRP composite

structure is stronger than steel, therefore a well designed composite

GRP hull structure utilizing combination composites (multi axial and uni-directional

fibres) will be close to steel in strength yet be much lighter than a

comparable steel vessel, however one of the great advantages of GRP is

that thickness and strengthening can be concentrated exactly where it is

required by locally increasing thickness at specific areas, something

that can not easily be done with steel. In pilot boarding impacts it is

the vessels fenders that absorb the impact cushioning loadings on the

hull structure, therefore that so long as the vessel is adequately

fendered, which the interceptor is, then the advantage of steel in

strength is effectively neutralized. Although

steel hull’s attribute to a lower cost of construction, it has some

distinct disadvantages: Weight The

steel vessel will weigh considerably more than an aluminium or GRP

vessel, this results in larger engines being need to power the vessel

with a very significant increase in fuel consumption and running costs

(especially so in today's environmentally conscious environment).

Therefore there is a distinct disadvantage attributed to the weight

penalty when dealing with a high speed craft. Maintenance As

steel is very prone to corrosion, yearly re-painting will be required

adding to service and maintenance costs. Superiority

over Aluminium Hulls Aluminium

has advantages over steel in weight; however these advantages do not

apply when compared to GRP. We

believe, GRP being a homogeneous structure, without welds and sheet

panel joins that can introducing stress areas, and without any concerns

over electrolysis and dissimilar metal corrosion that it is superior to

aluminium. Furthermore, maintenance and repair does not require

specialised skilled personnel as is needed with aluminium (skilled

aluminium welders). Good GRP repair and maintenance work can be easily

affected. Furthermore GRP produces a vessel of superior acetic finish,

its surface gell coat is of high gloss, and there is no ‘starved

dog’ appearance as occurs when welded frames in time show through on

an aluminium hulls construction. In addition maintenance costs are

greatly reduced as there is not re-painting required over the vessels

life, as is the case with painted aluminium vessels. Other

Considerations for GRP Hulls The

life of the vessels GRP structure should easily reach 15-20 years. One

important consideration in GRP boat production is the tooling costs to

design and manufacture the necessary moulds to build a GRP vessel. Many

companies cannot afford this investment or are not prepared to invest in

the appropriate tooling etc. SHM however has demonstrated that we are

prepared to invest in tooling to build superior GRP vessels.

Safehaven Marine, Ashgrove, Cobh, Co Cork, Ireland Phone 00353 86 8054582 Email- info@safehavenmarine.com safehavenmarine@eircom.net

|

All our vessels are build to the highest standards of strength & engineering and are renowned world wide for their exceptional sea keeping abilities. For the best, most extreme, rough weather demonstration videos of our boats, see our amazing selection on you tube.

BEST ROUGH WEATHER ACTION PHOTOS We don't just claim our boats have the best sea keeping abilities, here's the proof |

||||

| CERTIFICATION | |||||

|

See all our previous professional PILOT vessels |

|||||

|

See our spectacular rough weather video's |

|||||

|

See our recent newsletter |

|||||

|

WORK FORCE |

|||||