HOME MODEL RANGE CONTACT US GALLERY VIDEO DOWNLOAD PRICE LIST

SAFEHAVEN MARINE. Builders of the Interceptor & Wildcat range of offshore craft

The new 2006 model INTERCEPTOR 37 'GENESIS'

'PREVIEW' NEW GENESIS 2007 DEMONSTRATOR NEARING COMPLETION

Our new 2007 demonstrator is to be a Genesis 37. A very high specification craft fitted with twin Yanmar 380hp electronic engines to give a 30kts+_ max speed. Her interior uses all new materials featuring a maple wood interior as opposed to the standard teak finish, and a new sidelining colour of light blue grey. Below are some preview pictures of her. Click ere to see the page.

SEE THE SHORT CABIN COMERCIAL ANGLING CHARTER VERSION Click here to see her

Development is now completed on our replacement for the old Interceptor 38 model. Our all new Interceptor 37 called the 'Genesis' will commence production this Autum. Closely based on our hugely successful Interceptor 42’s hull, but incorporating a number of refinements to provide even higher levels of performance and seakeeping. Her beam is a wide 3.5m moulded, (12ft 4” overall) just 10" short of the 42’s beam, and much wider than the old 38’s, providing her with high levels of both static and dynamic stability. With a GM of 1.5m she has high reserves of stability over an anticipated large displacement range, as indeed she will form the basis for a new 37’ft Pilot Boat to be offered alongside the current Interceptor 42 ‘Pilot Boat’. Her waterline entry has been made finer at 58 degrees to cut through waves even better, and she has the same midships deadrise of 22 degress meaning she will not slam in large waves. And of course her steeply raked stem and cutaway forefoot means she has the same excellent handling in following seas. Her unique double chine hull design means she will be an exceptionally dry boat.

We have chosen an Island Wheelhouse design similar to the 28's for her superstructure, taking advantage of her wide beam, it provides loads of gunwale space for angling and a large deck area, but still provides good accommodation space, which can be varied to suit her intended role. Both long and short cabin versions will be available.

On Sunday the 24th Sept we launched the first Genesis 37. She looks fabulous and ran perfectly achieving 27kts.

We have now had the first good gale in which to sea trial the Genesis 37 in some rough conditions. In force 6 with a good 9-10ft sea she was fantastic. Her deeper V hull resulted in an even smother ride in head seas, whilst her wide beam and new keel design provided her with superb dynamic stability down wind in following and quartering seas. Her chine and spray rail design resulted in a dry ride. A few days later we had some heavy weather with force 8 gales allowing us to extensively sea trial her, again she acquitted herself with flying colors. Most notable was her amazing softness in head seas, her fine bow made her very gentle, almost like our Wildcat, which is saying something. Down wind, even in heavy breaking seas we were able to really gun her flat out, during which she was beautifully controllable and stable. In most conditions she was the equal of the 42 even considering her smaller size, and indeed it was only when beam on that, in comparison to the 42, was her size noticeable. Here the fact that she was 1,500kg lighter and smaller meant she was pushed around more.

All in all she has exceeded expectations, and will prove a successful replacement for our old Interceptor 38.

Above, even with her propeller out of the water her landings were soft and controlled , there's also a spectacular new video on both the performance and seakeeping section of our video download site, well worth viewing!

Her deeper V Hull really does allow her to push hard in to steep head seas without slamming, sea trialing in force 5-6 she easily maintained 16kts into 7-8ft seas in relative comfort.

Below can be seen being speed trailed. Her spray rail and chine arrangement worked as designed, peeling water away from the hull at higher speeds, but not impacting at lower speeds resulting in a soft ride. She achieved 27kts at 2560rpm, and cruises comfortably at 2200rpm for 23kts. An economical cruise of 16.5kts is achieved at only 1800rpm offering excellent fuel economy.

Sleek and gracefull, the Genesis 37 must be one of the best looking designs around.

Her superstructure has been offset to port to allow a good wide and safe passage up the st/bd side to the fore deck, this makes perfect sense as generally you only ever come along side, to the side with your helm, st/bd in this case, so why waste valuable accommodation by providing a walkway up the port side that never gets used. This way you get the best of both worlds, safe foredeck access and maximum accommodation. The design takes advantage of her wide beam in providing maximum gunwale space for angling, allowing anglers to fish from the full length of the craft when drifting. In addition she features a large aft cockpit area with a flush deck which provides plenty of space, but still allows for a large accommodation area.

Her interior design provides for spacious and comfortable accommodation. Twin CAB 300 series are fitted optionally here at the navigators station. Alternately a wider main helm position can be chosen, allowing a greater space for electronics.

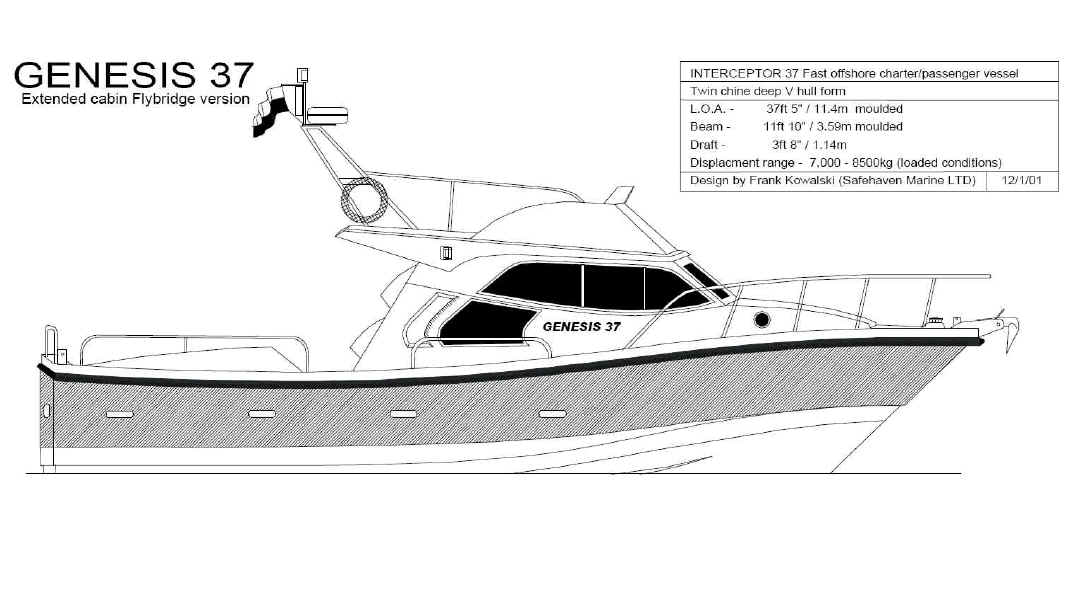

This is the extended cabin version, which provides greater accommodation area and more luxurious fit out including thicker cushions and the lower side window designs, which provide excellent visibility from inside.

Below- Special attention was paid to providing a very ergonomically comfortable helm position. There is no uncomfortable reach to the wheel and will provide for long fatigue free periods at the helm. Electronic screens are fitted free standing on top of the GRP helm console without affecting the drivers sight line and allow for future equipment changes.

Her large spacious flush deck.

Below- Her offset Island Wheelhouse provides a safe walkway to the foredeck and maximum fishing area.

The first craft is fitted with the new Caterpillar C9 @ 575hp. Easy access is provide right around the engine.

The Genesis 37's fine lines can be appreciated here. Her keel design has been optimized to provide the least drag and resistance and maximum directional stability. Because the Interceptor hull is a true deep V she has a deep draft at the bow and amidships naturally, so there is no need for a deep keel here, as her deep V sections act as a keel in itself. Only at the transom where her draft reduces is the keel needed and here it is deep, hydrodynamicaly optimized, and faired into the propeller tunnel to provide a smooth, clean flow of water to the propeller. This results in zero cavitation and a smooth, quiet ride. In addition a skeg protects the prop and rudder from ropes and floating debris.

Twin spray rails reduce wetted area at higher speeds, but are foreshortened at the bow to eliminate chine knock at low to medium speeds.

Her transom is curved and rounded at her sheer maximizing strength and freeboard as well as looking great. Her wide tunnel design can be seen, allowing up to a 28" propeller to be turned.

Her aft deck is be flush, and accommodates either single or twin engine options.

The most likely engine options are-

Standard vessel- IVECO M40 370 / 400hp or Caterpillar 3126 350hp

Engine upgrades to the following engines.

Caterpillar C7 455hp

Iveco M55 500 / 550hp

Caterpillar C9 575hp

Volvo D9 500hp

Volvo D12 650hp

The first boat is being fitted with Caterpillars new C9 at 575hp, Twin engine installations run from a pair of Yanmar 4LH 250hp up to a pair of 440hp Yanmar’s for maximum performance of over 30kts. Overall the new model will combine excellent seakeeping and performance with Safehaven’s now expected style and graceful looks, in a smaller, more compact vessel ideally suited for commercial charter work, or recreational use.

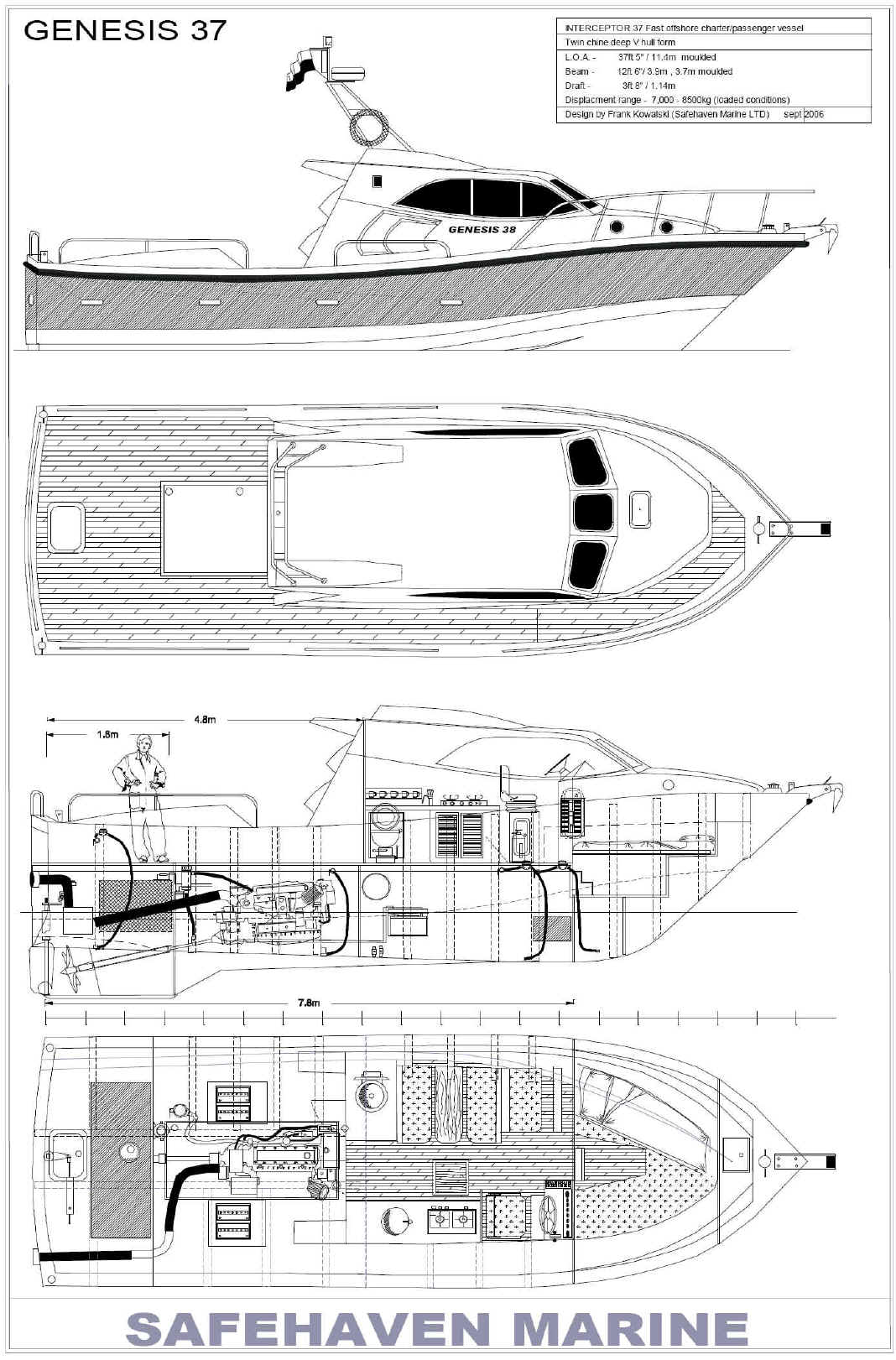

DESIGN SCHEMATICS AND G A DRAWING

Contents

Page

OVERVIEW

General

Description.

3

Classification

4

Principle

dimension

4

Speed

4

Hull

Construction

4

Deck

Construction

5

Wheelhouse

& superstructure construction

5

Bulkheads

6

Trails

& Delivery

6

GENERAL

ARRANGEMENT

Fore

peak

6

Forward

Accommodation

6

Engine

Compartment

7

Wheelhouse

7

Aft

Peak

7

MACHINERY

Main

engines

8

Stern

Gear

8

Exhaust

system

8

Steering

System

8

Engine

controls and instrumentation

8

Skin

fittings

9

SYSTEMS

Bilge

systems

9

Fuel

tanks

9

Fuel

Gauges

9

Fuel

system

9

Engine

cooling system

10

Fire

extinguishing system

10

Fire

proofing / protection

10

Alarms

11

Fresh

water installation

11

Heating

11

ELECTRICAL

INSTALATION

Battery

Installation

11

Lighting

11

Navigation

and Communication equipment

12

Electrical

Equipment

12

Cathodic

Protection

12

FIT-OUT

Hull

fendering

12

Windows,

hatches and doors

13

Deck

fittings

13

Mast`

13

Handrails

14

MOB

Recovery system

14

Life

Saving equipment

14

PAINTING

External

colours

14

Internal

finishes

15

Logos

/ Lettering

15

ADDITIONAL

INVENTORY

Spares

/ Documentation

DRAWINGS

& DETAIL SCHEMATICS

LLOYDS

SPECIAL SERVICE CRAFT REPORT

1

Overview

1.1

GENERAL DESCRIPTION

Vessel

Description.

The

GENESIS 37 is a GRP craft utilizing a double chine Deep V Hull design. The hull

has a wide 12ft 6” beam providing high levels of transverse stability. The

deep V hull design with 22 degrees dead rise amidships, 49 at the bow and 18 at

the transom gives excellent head sea performance with minimal pounding and also

provides safe and dependable down wind handling due to its cutaway fore foot,

and raked stem. The vessel is also very dry due to its double chine arrangement

and bow flare.

1.

2 CLASSIFICATION

The

hull and superstructure are to be moulded in general accordance with Lloyds

Register of Shipping (LRS) SSC Rules as applied to Vessels operating in area G3.

The Laminate weights and scantlings were determined using Lloyds Special Service

craft software, a print out is included in the appendix.

The vessel is approved by the MCA for category 2 (60nm) and by the IRL Dept of Marine for P5.

1.

3 PRINCIPLE

DIMENSIONS

Length

overall

38ft 4” / 11.9m

Length

moulded

37ft 6” / 11.4

Beam

moulded

12ft /

3.6m

Beam

overall

12ft 6” / 3.85m

Draught

4ft ” / 1.20m

Displacement

(approx)

7,000kg (lightship)

1.

4 SPEED

The vessel shall

provide for an operational speed of 18-25kts fully loaded. (depending on engine

choice)

1.5

HULL CONSTRUCTION

Hull

laminate schedule / lay up wts -

300gm2

using isophthalic resin. Composite

as follows-

900gm2 CSM. isophthalic resin

900gm2 CSM. isophthalic resin

300gm2 CSM stitched in combination too

600gm2 Woven Roving

900gm2 CSM

300gm2 CSM stitched in combination too

600gm2 Woven Roving

900gm2 CSM

300gm2 CSM stitched in combination too

600gm2 Woven Roving

Total

shell laminate Bottom -

6600gm2

Hull sides

300gm2

using isophthalic resin. Composite

as follows-

900gm2 CSM. isophthalic resin

900gm2 CSM. isophthalic resin

300gm2 CSM stitched in combination too

600gm2 Woven Roving

900gm2 CSM

Sides

- 3900gm2

Reinforcement

- Keel. Additional 2 x 900gm2 CSM layers extending min 300mm from keel

across bottom. Each layer stepped back 25mm.

Keel -

8400gm2

Reinforcement

- Chines. Additional 2 x 900gm2 CSM layers extending min 10” up sides

& across bottom. Each layer staggered min 25mm

Chines - 8400gm2

No

coloring agent used in lay up.

No

longer than 24 hrs between layers to ensure chemical bond.

Immediately

after cure of main laminate & whilst still in mould the following stiffening

is bonded –

SCANTLINGS.

The

vessel is TRANSVERSELY

FRAMED

at 600mm centres giving approx 400mm panel widths.

Transverse

frames- 100mm x100mm @ 600mm centers. Max

unsupported panel width, bottom –

450mm . side – 450mm. (measured between stiffeners)

Max span, bottom - 0.90m - 1.5m. side – 1.2m.

Lay up over frames

900gm2 CSM

900gm2 CSM

Min overlap100-125mm

Longditudal Panel breakers- Foam cored 50mm deep x 100mm wide in section, lay up-

900gm2 CSM

900gm2 CSM

1800gm2

total laminate, staggered, min

overlap 150mm. Max span .45m

Main Longditudals- Foam cored 200mm deep x 100mm wide in section, lay up-

900gm2 CSM

900gm2 CSM

1800gm2

total laminate, staggered, min

overlap 150mm. Max span 2.5m

Engine girders - Wood cored (multiple layers plywood laminated together) 4” wide x 5-12” high.

lay up-

900gm2 CSM

900gm2 CSM

900gm2 CSM

2700gm2

total laminate, staggered, min

overlap 150mm. Max span 2.5m

1.6

DECK STRUCTURE

½“

plywood, gell coated bottom, encapsulated 900gm2 top. Supported on

4”x2” longditudal deck beams @ 16”/400mm centres. Bulkheads notched to

receive and bonded. Multiple vertical support beams & webs as per drawing.

Deck shelf foam cored as per drawing and bonded to hull 1800 gm2. Hull to deck

join - 1800 gm2, min overlap 125mm.

1.7

SUPERSTRUCTURE / WHEELHOUSE CONSTRUCTION

The superstructure consists of a GRP moulding, attached to the deck stainless bolts @ 8” centres and GRP internal angles (1800gm2 min 150mm overlap)

Laminate weights on superstructure are 2100gm2 - 3600gm2 laminate. Additional wood cored stiffening overlaid 1800gm2.

Main roof scantlings are provided by 30 x 75mm transverse frames @ 600mm centres across roof structure. All glassed into superstructure using 1800gm2 laminate with min 50-75mm angles.

Internal partition bulkheads & wood work (seating, lockers etc ) forming additional stiffening to structure which is al glassed into the side laminate.

Engine

vents are inboard along the inside of the gunwale.

Non slip deck coating applied to top side walkway.

The aft cockpit gunwale is a GRP Moulding of 2100gm2 through bolted to the hull sides @ 150mm centres with GRP stiffening plates additionally glassed in approx 1,2m spacings.

1.8

BULKHEADS

Three

Transverse bulkheads as per drawings constructed from ½ ”/ 12mm plywood

overlaid 600gm2 per side with 50 x 50mm vertical webs to provide extra

stiffening. The b/heads are set on to the hull by being positioned on top of 50

x 50mm foam cored framing as per drawing to prevent formation of hard spots. And

are laminated to the hull using 1800gm2 laminate with a min 6” overlap.

Additional

collision b/head is fitted in the bow.

Materials

-

All Lloyds approved GRP materials (resin & glass) used in the construction of hull. Details provided.

1.9

TRAILS

& DELIVERY

On

completion and launch builders trails are to be carried out with an engine

manufactures representative aboard and the engine installation to be approved.

Customer

trails: Prior to hand over a full set of trails will be completed in Cork

Harbour and will include a two way run between the green and red buoys marking

the channel between the Oil Refinery and East Ferry in order to verify the

crafts maximum speed. Maneuvering & handling trials

Will

be completed to determine the crafts

handling, and rough weather trails off Roches Point will be carried out to

determine the crafts sea keeping abilities.

A

full check on the operation of all the crafts systems and electronics will be

carried out.

All

trials to be carried out with 100% fuel, & 2 crew.

On

completion and acceptance of the vessel the craft to be handed over at East

Ferry Marina in

WARRANTY

Safehaven

Marine shall provide a 12 mth warranty against any defective workmanship or

component fitted to the craft. Equipment shall carry a 12mth warranty. The

Engine shall be covered by the engine manufacturers own 12 mth, or where

extended warranty.

2.1

FORE

PEAK

The

fore peak extends forward of the collision b/head and is a void space provided,

capable of being used as a storage area. There is full access to all fittings.

2.2

FORWARD

ACCOMMODATION

Depending

on the chosen GA arrangement, but in general comprises a V Berth with 2”

cushions, The heads compartment positioned under the helm, there is a removable

hatch allowing access to all electrical components and fuses. The area is flow

coated white. A manual sea toilet is fitter with sea cocks exiting in the

compartment aft and being capable of easily reached for shut off.

The

galley can be positioned in this compartment, comprising 2 slide out teak

lockers, a 2 burner gas hob.

GAS INSTALLATION

This

cooker is served from a dedicated gas supply with the gas bottle stored in the

aft cockpit in its own dedicated locker

which is vented overboard. The Gas run is in 10mm copper and uses correct

compression fittings throughout the installation.

Where

required to code (optional) a gas alarm is fitted with the sensor mounted low down in the bilge.

2.3

ENGINE

COMPARTMENT

The

engine compartment is accessed from the aft cockpit by either a W/Tight large

GRP engine hatch that is flush to the deck, or by an engine box with a raised

side coaming 320mm above the deck level, Hatches are securely closed when at sea

by an appropriate amount of locking mechanisms.

The

engine compartment is flow coated grey providing a smooth surface.

2.4

WHEELHOUSE

The

Wheelhouse has The helm position to port or st/bd, is fitted with a CAB 300

Series hydraulic damped and sprung

helm set on a pedestal. Adjustable for height and fore and aft adjustment.

The

cabin is fitted a 4 person dinette with table between. A L shaped bench seat is

opposite its size being dependent on whether the heads is in the fore cabin or

the main cabin accessed from the aft cockpit. The layout will depend on the

chosen GA but will be similar to the above description.

The

floor surface is lined with studded rubber. An access hatch provides access to

the void space below.

2.5

AFT COMPARTMENT

Access

to this area is from a GRP hatch situated deck aft of the cabin entrance.. This

area contains the fuel tanks. Rudder and steering gear and exhaust outlets.

MACHINERY

3.1

MAIN ENGINES

The

vessel is fitted with a single Iveco 380hp engine and ZF Gearbox 1.75:1 ratio or

alternative manufacturers engine. The engine is fitted with adjustable flexible mountings.

The engines are mounted on 125 mm thick wood cored engine beds bolted through

taped glassed in 12mm steel with 14mm bolts.

The

machinery is installed in accordance with the manufacturers recommendations and

installation instructions and commissioned by the appointed agent / engineer and

tested to provide conformity with the manufacturers recommendations.

Care

and attention is paid to providing durable machinery installation with adequate

support and neatness on all piping and cable runs. Special attention is paid to

provide ease of ongoing maintenance and ensuring all service items are readily

accessible. All piping and

connections to the engine and throughout the overall installation are to be of

an approved type.

3.2

STERN GEAR

Stern

gear is provided by Clements engineering in the UK, consisting of:

44mm”

stainless steel Aqualloy 30 or equivalent.

Glass

in P bracket with cutlass bearing

GRP

Glass in type stern tube assemblies with cutlass bearing

Drip

free PPS or equivalent water lubricated stern tube seal

Rudder

assemblies fitted with bronze blades, steering quadrants, O ring seals and PTFE

type bearing also packed with grease through nipple.

GRP rudder tubes, glassed in to hull bottom and reinforced as

appropriate. 38mm solid steel tie bar, 20mm ball joints with 20mm bolts through

tiller arm.

Square

rudder stock allows fitting of an emergency tiller arm through a deck opening.

R&D

coupling between the shaft half coupling and gearbox flange.

4

Blade 25” propeller.

3.3

EXHAUST SYSTEM

The

exhaust system is a wet type run from each engines exhaust and exciting the

transom via a Vetus exhaust outlet fitted with a non return flap. Vetus 6”

exhaust hosing with double stainless claps on each connection. The exhaust

system is designed to prevent back flooding of water to the engines and shall

meet all engine manufacturers requirements regarding fall and back pressure. 6

3.4

STEERING SYSTEM

The

vessel is fitted with a hydraulic steering system consisting of a Vetus MTP42R

Hydraulic steering helm pump. MTP 125 steering ram providing the craft with a

hard over to hard over of 6 wheel turns without being overly heavy in steering

effort. Fitted with a bypass valve to allow operation via the emergency steering

tiller arm. The system uses 10mm copper piping and compression fittings

throughout, with a section of flexible hose at the steering ram to absorb

steering ram movement.

An

emergency steering tiller can be supplied (optional) and stowed in the aft compartment.

3.5

ENGINE CONTROLS & INSTRUMENTATION

Single

lever Morse controls with cables fitted at the main helm positioned,

ergonomically positioned for ease of operation.

The

engine panel is fitted with the standard manufactures instrumentation

comprising-

Tachometer

Oil

Pressure gauge

Water

temperature gauge

Battery

voltmeter

(may

differ according to manufacturers spec)

3.6

SKIN FITTINGS

All

skin fittings used throughout the vessel are of a suitable marine grade material

and are fitted with ball type, lever operated shut off valve in the engine

compartment. All underwater valves are fitted with twin stainless steel jubilee

clips.

4.1

BILGE PUMPING SYSTEMS

The

craft is sub divided into four compartments..

Each

water tight compartment is fitted with one diaphragm type pump of 90 ltre p/m

capacity of 1 ½” dia piping.. Where a bilge run passes through a b/head it

does so through a s/steel b/head fitting as high as practicable in the b/head.

The bilge system exits the hull above the W/L via a shut off valve. Each pump is

clearly labeled for its operation.

In addition the engine compartment has a Jabsco 25mm self priming pump of 20lpm capacity, automatically activated by a float s/w sensor and an audible alarm at the helm.

4.1

FUEL TANK

Fuel

tank position is in the aft compartment outside the engine compartment. The

craft is fitted a Plastic fuel tank of approx 200 gallons capacity, to be

constructed from 12mm plastic welded, (or where required by rules as an option

of 2.5mm 304 grade stainless steel.) It is fitted on prepared beds in the aft

compartment and bolted to the aft engine room b/head and bonded attachment lugs

to the support beds (aft section of engine bearers, level and continued aft to

transom)

The

tanks are fitted with a suitable no of baffles, in general giving a maximum

unbaffled volume of 25 gallons

Each

tank is fitted with fuel take off and returns as well as venting. The fuel runs

use hydraulic hose from the tank to a through b/head hose fitting in the aft

engine room b/head, and from the other side to the fuel filters and on to the

engine with chrome plated copper piping. A short section of hydraulic hose runs

from the end of the steel pipe via a suitable fitting to the engine.

Fuel

fillers are positioned on top of the tanks and accessed via round inspection

hatches (150mm dia) on the aft deck. Fuel shut of valves are fitted here

(outside the engine compartment)

4.2

FUEL GAUGES

As

an optional extra each tank can be fitted with a sender unit and a fuel level

gauge at the helm console.

4.3

FUEL SUPPLY SYSTEM

Fuel

piping is of 15mm chrome plated copper or H/D hydraulic fuel hose where regulations applicable. Each tank is fitted with a VETUS WS720 series fuel

filter with a flow rate of greater than 180lt/hr and fitted with a glass bowl.

The system is arranged so that each engine feeds from and returns to its own

dedicated tank. A shut of valve is fitted in the aft compartment at the tanks.

4.4

ENGINE COOLING SYSTEM

Each

engine is cooled by a heat exchanger. The raw water is fed to each engine from

its own 2” dia sea cock, fitted with an external grill and filtered by a

H/D Aquafax type (clear glass top) water strainer. The position of the raw water

intakes is carefully considered to provide a continuous supply of water to the

engines in rough conditions. Hose connections to the engine are double clipped

and the hose is of an approved fire proof type.

The

waste water from the engine is piped to the exhaust outlet elbow. A feed of

waste raw water is taken to the water lubricated stern glands. The feed from the

gland is in copper pipe and extends 400mm above the w/l, from which point it is

in suitable flexible hose to the engine.

4.5

ENGINE ROOM VENTILATION

Intake

air is supplied through a ventilation stack on the inside of the gunwale where

there is least spray. The vents are inboard facing, a dorade system is built

into the stack to prevent any water from entering the engine compartment. Air is

bought to the engine room down through a deck opening. A manually operated fire

flap is fitted allowing the engine room to be isolated in the event of fire. The

size of the ventilation is commensurate with the engine manufacturers

recommendations.

4.6

FIRE EXTINGUISHING

SYSTEM

Fire-fighting

equipment.

Optional

extra, fitment at owners request.

·

A Co2gas flooding system is used to extinguish fire in the engine

compartment. Two 5 kg extinguishers (calculated by the recommended formula to be

suitable for the volume of the compartment) is situated outside the engine

compartment and are manually operated from the main cabin, outside the engine

compartment by means of a cable. The co2 gas is piped to the engine compartment

using 10mm copper pipe and compression fittings.

The

quantity of Co2 provided has been calculated to be sufficient to occupy at least

60% of the volume of the engine room compartment based on 0.56 cubic meters per

kg of liquid.

The main engine

room ventilation is positioned as per drawing. Of a size specified by engine

manufacturer. Situated on or about the vessels centre line with its opening

positioned .6m above deck level. Fitted with a closable flap manually

operated from the front of the ventilation box whereby the flap will close

off the engine room and allow the injected gas to extinguish the fire.

In the event of fire in the engine room the following provisions are made to prevent flooding.

The main raw water intake in the engine compartment uses fire proof exhaust hose to connect the engine to the sea cock via the strainer.

All

outlets in the engine compartment

use lever type shut off valves.

4.8

ALARM SYSTEMS

A

high level bilge alarm is fitted inside the engine compartment. An audible alarm

id fitted at the helm station. Automatic float level switches automatically

operate the bilge pumps in the event of flooding.

A

GAS ALARM is fitted where required by regulations. (optional extra)

4.9

FRESH WATER SYSTEM

The

craft is fitted with a 100 litre plastic fresh water tank. The system is pressurized

and distribution is by whale O’Ring type fittings and plastic

pipe. The tank is filled from a deck filler. The water tank also feeds a

windscreen washer system. (optional)

4.10

HEATING SYSTEM (optional)

A

hot air heating system is optionally fitted, a type whereby hot water from the

engine is used to heat a radiator and provide hot air trucked to the helm

station from where three adjustable outlets provide hot air to demist the

screens. A fourth outlet can be provided to the forward accommodation area.

ELECTRICAL

INSTALLATION

5.1

BATTERY INSTALLATION

The

electrical system is 12V. (24v optional) Two h/d batteries (engine starting) are

fitted in a dedicated vented boxe inside the engine compartment, fitted with a

remote operated 3 position isolator switch (operated from outside the engine

compartment) This is a parallel circuit isolator

S/W allowing switching between battery

banks (service and engine start) in an emergency should one bank fail.

A

second bank of one battery fitted in a dedicated vented box under the f/wd

accommodation sole and is dedicated to service & equipment supply.

A

DC distribution board and switch panel fitted with 12 circuit breakers /

switches, one for each of the main circuits.

All

cables are conduit run as required and all cables are securely clipped supported

and protected for operation in rough weather. All connections and junction boxes

mounted as high in the vessel as practicable and are of an approved marine

quality.

5.2

LIGHTING.

One

light in the forward accommodation area.

Toilet

light

Two

overhead quartz halogen lights in the main cabin

Single

Vetus round in the main cabin by door

Navigation

lights

Anchor

light

5.3

NAVIGATION & COMMUNICATION

EQUIPMENT

The

vessel can be fitted with an electronics package of the owners specification and

supply.

The

Radio equipment fitted will be to the licensing authority’s requirements, an

example is shown below for approval purposes only

Raymarine

C120 plotter / 24N/M Radar combined

Simrad

DSSC VHF Radio

Hand

held radio

Depth

sounder / fishfinder

ERIPB

5.4

ELECTRICAL EQUIPMENT

One

pantograph windscreen wiper.

Vetus

water system pump

Bilge

alarm panel

Engine comp bilge pump

High level float s/w

High level float alarm

S/W Pannel

Isolator switch

5.5

CATHODIC PROTECTION

Anodes

of a suitable size are to be fitted, one per engine to provide a one year

service life. All sterngear is wired to the system and tested for effectiveness.

FIT

OUT

6.3

HULL FENDERING

As

standard 75x75mm H/D rubber fendering is fitted around the gunwale top. Bolted

with 6mm s/s bolts @ 150mm centres with a 5x50mm aluminium insert. Silkaflex

bonding adhesive is used in fitting the rubber to the hull. Very heavy duty

fendering up to 120x120mm can optionally be fitted as can a second lower line

and diagonals if required.

6.4

WINDOWS & HATCHES.

The

windows used throughout the craft are supplied by M.W.F. are of high quality

clamp in type utilising 6mm toughened glass and secured in place with silkaflex

and are fitted as shown on the GA drawings. Comprising:

3

front

2

side opening

1

aft cabin b/head

Single

escape hatch, Vetus type fitted overhead in the forward accommodation area.

The

main wheelhouse external door is of a H/D plastic design with corrosion proof

fittings.

6.5

DECK FITTINGS

All

deck fittings are fitted with backing plates. The following mooring arrangements

are provided.

One

large mooring bollard f/wd at the bow.

Two

large mooring bollards at the transom quarters.

Two

large midship spring cleats

A

bow roller is fitted at the bow

6.6

MAST

A

Stainless steel A frame type mast is constructed from 50mm s/s mirror polished

as per the GA drawing with mounting point for a GPS, Ariel and Radar.

6.7

HANDRAILS

All

external handrails are fabricated from 25mm dia 316 polished stainless steel

pipe and bolted to the superstructure with round backing plates with internal

concealed fixing (12mm bolts)

A

bow railing extended back as far as the end of the fore cabin. A single

horizontal rail is used.

A

railing extends around the aft cockpit to a minimum height of 1m above the deck.

A second horizontal rail closes the gap to a minimum width of 9”

Chain

closures are used by way of access breaks in the railings.

In

addition throughout the craft where necessary there are fitted a number of

vertical 25mm grab rails where necessary to allow for safe thoroughfare.

6.8

SCUPPERS /

COAMINGS

The

aft cockpit contains a number of

large scupper to clear any water on the aft deck. A minimum of two 250cm2

scuppers are fitted in the transom four additional scuppers are positioned

evenly along the vessels side. Where fitted the vessels engine boxes coaming is

320mm above the deck.

6.9

MOB RECOVERY (optional)

A

ladder is fitted at the transom to allow access to the waterline.

6.10

SAFETY EQUIPMENT

Owner supplied

Liferaft

of a type approved by the Licensing authority, capable of containing all crew

members fitted to superstructure roof and fitted with a hydrostatic release

system.

Owner supplied

2

30” dia orange life buoys fitted with lights and one fitted with 100m line.

6

no Self inflating Dept of Marine approved life jackets

2

no Safety Harnesses

Boat

hook man overboard recovery pole

1

no Category C first aid kit

Offshore

flares in poly bottle.

PAINT

& FINISHES

7.1

EXTERNAL

FINISHES

Antifouling

Red / blue

Fendering

Black rubber

Deck

owners choice of non slip colour

Superstructure

White

7.2 NAME & LOGO

7.2

INTERNAL FINISHES

In

general all surfaces in the main cabin are carpeted where practical in blue or

beige carpet.

Otherwise

surfaces are painted in grey flow coat.

Headlining

is White foam backed vinyl on removable 4mm plywood panels.

The

forward accommodation is where practical carpeted otherwise surfaces are flow

coated white.

The

heads compartment is flow coated white.

Woodwork

in general uses teak faced plywood with teak trimming throughout

2

coats of matt varnish is applied.