HOME

MODEL

RANGE CONTACT

US GALLERY

VIDEO

DOWNLOAD PRICE

LIST

SAFEHAVEN

MARINE. Builders of the Interceptor & Wildcat range of

offshore craft

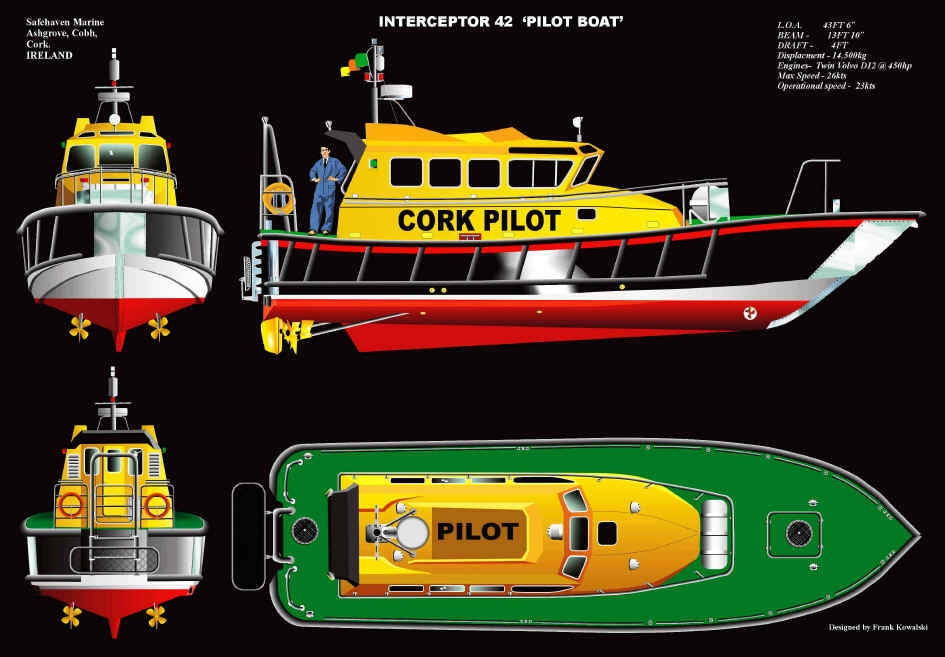

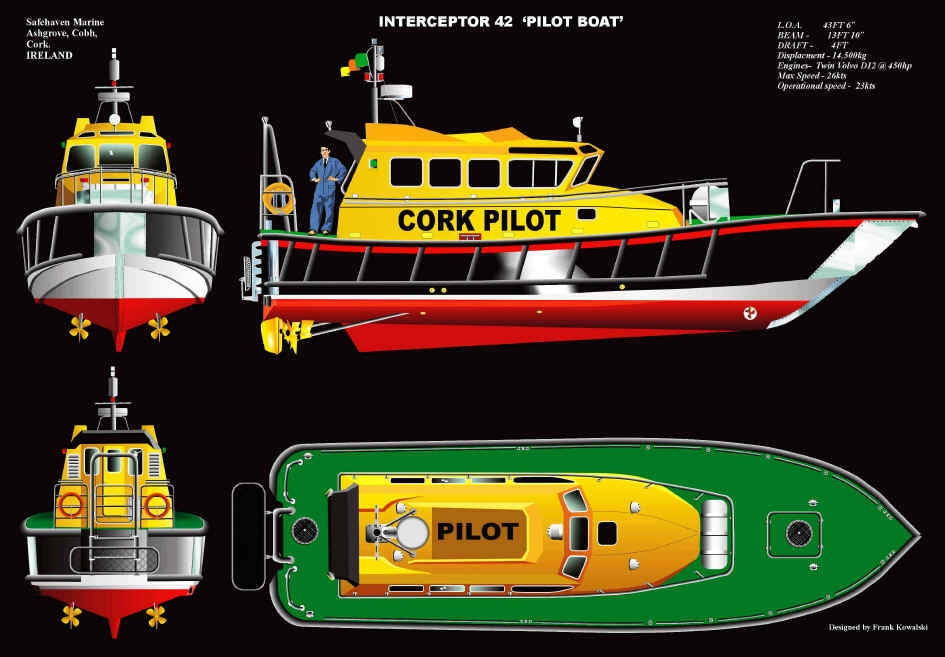

Interceptor 42 'Pilot'

'Gleann

Mor' The ‘Interceptor Pilot 42’ for the

Port

of

Cork

SEE

THE ROUGH WEATHER SEAKEEPING VIDEO IN STORM FORCE 9

'Gleann Mor' The first of class

Interceptor ‘Pilot 42’ was launched on

Sunday the 23rd April 2006

. Based on the very successful Interceptor 42 hull, which has seen service as

class 6 passenger boats, work boats, dive boats and patrol boats, with over 20

craft now in operation throughout the

UK

, and

Europe

. The hull design is well proven and renowned for possessing excellent sea

keeping abilities. Her LOA is 43ft , beam 14ft. and draft 4ft 6”.

In summer 2005 the contract was

awarded to Safehaven Marine to build the new pilot boat for the

Port

of

Cork

. One of the main requirements of the

port

of

Corks

specification was for exceptional strength. To achieve this, substantial

150x150mm transverse frames @ 500mm centers on a 10,000gm2 shell laminate were

used. The same substantial beams were used on the deck structure and knees which

provides strength at the critical deck to hull join. The Ports specification on

strength of design was very specific and size for size the “Gleann Mor” is

one of the strongest pilot hulls available and most people get quite a shock

when the see inside her. The net result is that the likelihood of damage

occurring to her hull as a result of normal pilot boarding operations is

substantially reduced, meaning less down time, an important consideration for a

busy port like Cork Harbour. Her main fendering was provided by Technix Rubber,

consisting of 160mm heavy D section, with 140mm D section used for the lower

belting and the diagonals. This combination provides good protection to the

craft when alongside ships. On deck, a wide walkway, 32mm railings and Hadrian

safety rail facilitate safe passage. During the consultation process with the

Harbour Masters and Pilots at the design stage, the importance of a particularly

wide space at the pilot boarding area was stressed. This has been created by

tapering the fore cabin strongly towards the bow. The life raft is stored in an

easily accessible position on the fore deck, and is protected from boarding seas

by a mirror polished protection plate, incorporated into the forward railings.

Below, her graceful lines can be appreciated in

this photograph.

In the cabin, the arrangement chosen

by the

port

of

Cork

was for a central helm position. This means boarding can take place to the side

best suited to the prevailing conditions, as both port and starboard side

benefit from equal visibility. In addition the helmsman’s seating and steering

position has been designed with car like ergonomics in mind, allowing fatigue

free operation, where all controls fall easily to hand. Visibility is maximized

by the use of forward slopping front windows, to easily shed water and reduce

glare and reflections. Upper level skylights and roof windows give a clear view

overhead. Front screens are heated and in addition a hot air heater / demister

is fitted to ensure good visibility at all times. Instrumentation and

electronics have been positioned to provide easily viewed navigation and vessel

information. A comprehensive electronics package was provided by Dunmast and

consists of three Raymarine 12” E series screens, two at the helm position

providing GPS plotter navigation, sounder and radar, with a repeater positioned

at a second position. In addition, an AIS readout and rudder angle position

provides further information. The layout inside is quite unique. Instead of the

usual six pilot seats, (which can be accommodated if required) there are four

pilot seats, the aft two have a table in front, and one has a navigation console

with full E120 repeater and VHF incorporated. This provides the pilot with a

very comfortable seated position, his own navigation station and access to

important information, particularly in adverse weather conditions while

communicating with approaching vessels. Cameras positioned on the wheelhouse

roof and at the transom provide the helmsman with selectable video images

displayed on the E120 units, of both the pilot boarding overhead, and the

transom waterline area. The latter will be invaluable to the coxswain in the

event of an emergency recovery as normally the area directly below the transom

is not visible from the helm. In the event of a MOB situation arising, recovery

will be easily facilitated by a MOB recovery basket which is single handedly

deployed down to below the WL, allowing an unconscious person to be recovered

efficiently in a horizontal position and lifted up to the weather deck. When not

in use the system folds back into the transom out of the way.

The main cabin is finished in a

combination of durable grey laminates, black GRP moldings for helm and seat

pedestals, and the cabin is lined in a grey sidelining carpet, providing

insulation and a warm environment. Access to the forward accommodation is

through a water tight hatch, steps leads down to a spacious area containing

seating and occasional berths. There is also plenty of storage space, a galley

with a 24v hot water boiler providing hot water for the crew. A separate heads

compartment is situated to starboard.

The vessels electrical installation

was carried out by Marine Electrical Services, Gabriel Whitston has over 25yrs

in Electrical engineering in the Irish Navy and the resulting electrical

installation is to an exceptionally high standard. The main electrics are

contained in a dedicated, dry and sealed compartment. The Electronic

installation is mainly Raymarine equipment and was supplied through Dunmast. The

Engine compartment is accessed from the fore cabin through a water tight door,

with a clear walkway up between engines. All service components have been

positioned in an easily accessible manor and care has been taken to ensure an

amount of redundancy within the engine installation, an example being the raw

water supply, which uses a large stainless central filter box, feed from a total

of four individual seacocks, This was a port requirement from experience with

their other pilot vessels giving a redundancy factor that should up to three

become blocked, there will still be an adequate water supply to the engine.

Bilge pumping is by both mechanical, engine operated pumps and hand operated

pumps, in addition electrical pumps also serve the engine compartment.

She is powered by a pair of Volvo D12

engines rated at 450hp @ 1800rpm continuous. This provides her with a required

operational speed of 22kts on a 17,000 kg displacement, being cognizant of fuel

costs and efficiency. Another part of the

Port

of

Corks

specification was to provide a means of quick engine replacement in the event

of a failure. To this end a large hatch is built into the superstructure roof

which can be quickly removed, the four pilot seats can then be unbolted ant the

completed seating modules removed. A large hatch situated in the cabin sole is

unlatched and hinged back, allowing the engines to be quickly removed. Clements

engineering based in the UK have supplied all of Safehaven Marines stern gear

over the years and were instrumental in the vessel achieving her performance

through consultation and advice on optimum propeller size and sterngear.

The first series of sea trials were

recently completed and her sea keeping was tested in severe weather conditions,

Storm Force 10, 60kts of wind and 10m seas with wind against tide at the

entrance to

Cork

Harbour

. Punching into steep head seas her behavior was as excellent. Her deep V hull,

weight and strength allowed her to punch through the waves almost silently with

no bangs or slams and even after being airborne her landings were very soft,

after shouldering the seas aside. The aft central con position and pilot seating

resulted in very low motions for the crew, providing comfort even in these

conditions. She was run her at various angles in to the seas. Beam on she was

excellent with very little rolling and heel and was able to withstand heavy

breaking seas striking her. Its worthwhile to note also that the screens

remained virtually dry throughout the test, her twin chine hull design

effectively suppressing airborne spray allowing good visibility to be

maintained, even in poor conditions. Turning to run before the seas she was

reassuringly controllable, allowing hands off steering in following seas,

running straight down wind displaying exceptional directional stability. Putting

the seas on the transom quarter, always a test for a boat, she was again very

steady, with little heeling on the face of waves when surfing and zero tendency

to yaw. In fact her stiffness and stability on this course was very impressive.

During ship boarding trials her

ability to easily come away from a ship provided great confidence to the

coxswain and crew; her deep V hull design creating a large wedge of water

between the two hulls, pushing her off easily by use of the wheel alone. She was

also very dry and stable when alongside. The

Port

of

Cork

will be carrying out extensive sea-trials with the Glean Mor over the coming

weeks and particularly in any adverse weather conditions.

The accompanying photographs clearly

distinguish the Interceptor Pilot 42, outlining the sleek and graceful lines and

colour scheme yet concealing the inner strength and design features so important

to a working vessel required for operations 24 hours a day in all weather

conditions.

The following dramatic

photographs are testimony to her seakeeping abilities. These pictures were taken

in a force 10 storm with 60kts of wing and 10m seas.

Cork Pilot boat in severe storm force 10,

70mph winds. Extreme conditions.

SEE

A VIDEO OF HER UNDERTAKING PILOT BOARDING'S IN STORM FORCE 10 & 10M SEAS

The sequence of pictures below show her coming

alongside a freighter during pilot boarding operations.

SEE

A VIDEO OF HER COMING ALONGSIDE SHIPS DURING BOARDING TRIALS

SEE

A VIDEO OF HER IN SERVICE UNDERTAKING PILOT TRANSFERS

Below, her interior is

bright and airy, fully lined and carpeted, she’s quite luxurious. The central

helm allows good all round visibility and the seat / steering interface is very

comfortable. Pilot seating is also very comfortable, two of which have tables

and one features a navigation console with VHF, GPS and radar repeaters. Several

vertical poles allow safe passage throughout the cabin in rough conditions

Below- Strength. The hulls scantlings are very closely

spaced @

500mm centres giving a 4300mm

panel width, the frames themselves are a huge 150 x 150mm (6" x 6") resulting in a

massively strong structure.

Below you can see the frames laminated in the hull.

PAn essential design feature was the ability to

quickly and easily remove an engine, shown below.