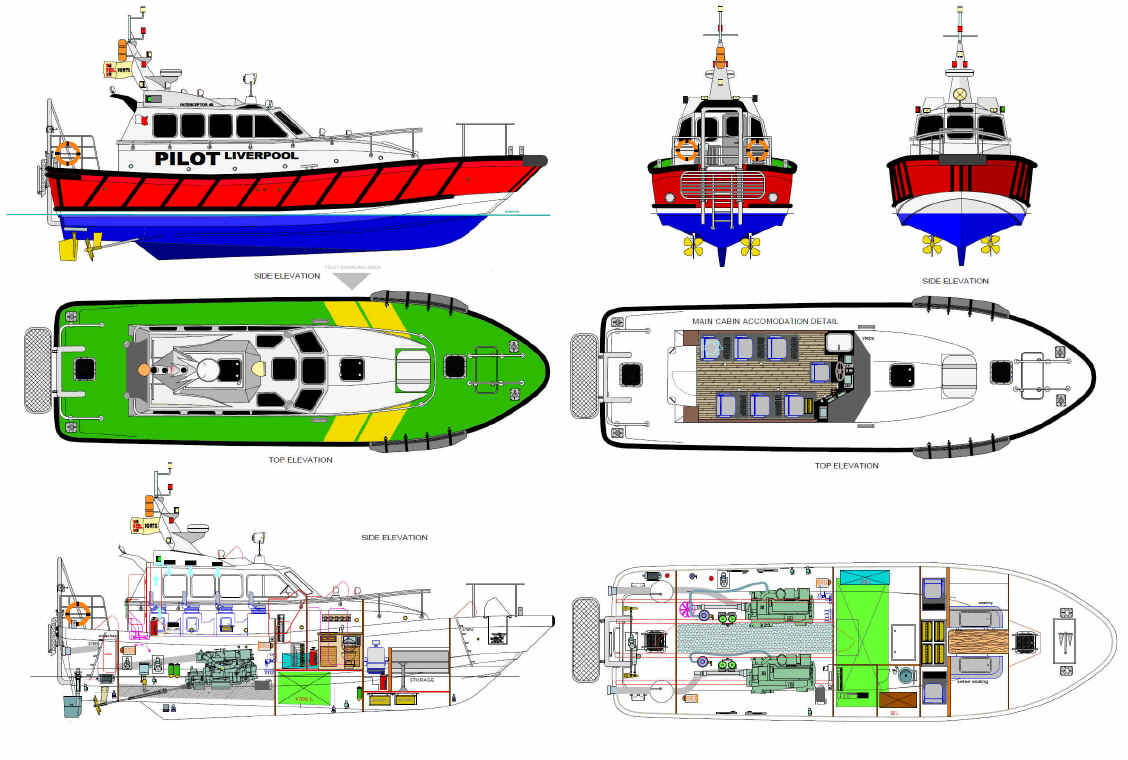

'TURNSTONE'

a 2nd new Interceptor 48 pilot vessel for the

Safehaven

Marine have launched a 2nd new pilot vessel for the

Turnstone

is the 5th of Safehaven Marines Interceptor 48 pilot vessels to enter service in

Ports worldwide, and is the 25th pilot vessel built by Safehaven Marine

demonstrating Safehaven's pre eminence in this specialized field.

'Turnstone'

is powered by a pair of Volvo's new D13 550hp engines and twin Disc 5114

gearboxes and achieved 26kts on sea trials, providing her with an operational

speed of 25-26kts, light / fully loaded. The vessel is 14.7m LOA, with a 4.3m

beam and 18,000kg Displacement. She has a seating capacity for 7 pilots and two

crew, Grammer air suspension seats

are fitted in the main cabin, with a further two in the forward cabin, which is

very luxuriously fitted out with a full galley, 4 person dinette and a separate

heads compartment. The pilots are well catered for with the vessel featuring air

conditioning with high level outlets throughout the main cabin providing a

comfortable environment. Double glazing on all windows ensures good visibility

is maintained at all times without the usual problems of misting in poor

conditions. A very high level of fit out has been undertaken, with teak and holy

cabin soles, walnut Formica laminates and trimming ensure Turnstone provides a

luxurious working environment, augmented by very low noise levels of just 75db.

'Turnstone' is very heavily fendered with 150x150mm D section rubber main

gunwale fendering augmented with Safehaven's unique sacrificial shoulder fender

system, ensuring pilot boarding's in rough conditions are soft, with impacts

well cushioned and the main fender and hull structure fully protected. Multiple

diagonals and a lower run further protect the vessel, Additionally an Ocean 3

fender fitted on her rounded bow allow the vessel to be used for occasional

'pushing' duties ,to assist pilots in small ship maneuvers. A full electronic

package supplied by Raymarine based around the E 140 / 120 series displays are

positioned flush in a GRP 'wrap around' helm console giving the helmsman

excellent command of the vessel, with all displays clearly visible, Safehaven's

usual special attention was applied in providing the utmost comfort and control

for the helmsman.

Other

features are a Victron 240v 3.5kw alternator, powered by a pair of auxiliary

alternators fitted to the engines allowing onboard 240v supply when underway.

MOB recovery is carried out by a further refinement of Safehaven's tried and

tested transom operated recovery platform, allowing an injured pilot to be

safely recovered from the sea unconscious. Special stainless rear view mirrors

were developed by Safehaven at the ports request and prove very useful during

boarding maneuvers. Electro hydraulic trim flaps fully protected in recess

mounded under the transom and enclosed in stainless steel guards for protection

from debris, and provide control over running trim allowing the bow to be

lowered for punching through steep head seas, something Safehaven's 48 is highly

adapt at, indeed the reputation Safehaven have established for building pilot

boats able to deal with the harshest sea conditions was contributory to winning

the original contract, with the Interceptor 48 by now fully proven and capable

of operating in storm conditions and 7m+ waves. She has been found to be very

relaxed and comfortable in a seaway. Safehaven

are currently building an Interceptor 48 for P&O Maritime for operation in

the Port of Matubo, Mozambique, a Search and rescue vessel for the Faroe Islands

and a S.A.R. Ambulance vessel for the Port of Chittagon in Bangladesh and

continue to prove themselves one of Europe's most successful boat builders.

Above and below, 'Turnstone' offshore in a gale demonstrating her excellent seakeeping abilities.

Technical

specification

Type

of vessel

Pilot boat

Owners

Peel Ports, Port of

Builders

Safehaven Marine

LOA

14.7m

Beam

4.4m

Draft

1.3m

Displacment

Lightship

17,900kg

Loaded

20,500kg

Construction

material

GRP

Engines

Volvo D13 550hp @ 1900rpm

Gearbox

Twin Disc 5114

Generator

3.5kw Invertor charged by 4x

90amp alternators

Propellers

28" 4 blade

Speed

Operational 25-26kts @ MCR

Range

220nm

Fuel

1,700 litres

Water

170 litres

Air-conditioning

Dometic 18,000btu

Seating

capacity

2 Crew, 7 pilots

Liferaft

RFD 12 persons

Certification

Bureau Veritas /

Several new features have been incorporated in Turnstone as part of our 'continuous improvement' practice incorporated on our 2012 year model pilot vessels.

Turnstones Bow boarding fender is supplied by 'Ocean 3' fender, offering greater durability, offering high compression resistance when pushing against quay walls and ships.

Additional

safety railing fitted at rear of cabin offering additional hand holds for pilots

when waiting at stern to move forward for boarding opportunity, and assisting

cabin access.

Modified

Sacrificial fender securing, replacing ratchets with our own design of

tensioning mechanism, reducing trip hazard and much less prone to damage due to

their lower profile, we have also been able to dispense with the aft tensioning

ratchets. In addition the SF fender is positioned further forward to allow the

pilot boarding ladder to lie in the gap behind it when the SF fender is touching

the ship, thereby preventing the ladder getting trapped between the pilot boats

fender and ships side.

Directional

vents for cabin heater / demister at the helm position allowing air to be blown

directly on the helmsman. In additional at the helm is a control to regulate

heat from the blower selecting hot or cold. When cold is selected low level

intakes draw cold air from the cabin allowing the helmsman to have a direct flow

of air conditioned air on him in summer when the air conditioning is in use.

The main cabins inboard external railing has been wrapped in black nylon twine

to improve grip and reduce slipperiness of the rail for pilot safety.

Above

left, twine wrapped railing, right bow access bow railing design.

Turnstone features the incorporation of stainless steel hinged guards on the trim tabs hull recess preventing floating flotsam, which is a problem in the River Mersey, from becoming lodged in the recess jamming and damaging the trim plates / hydraulic cylinder.

Above

left trim tab guards, right new larger rudder design.

We

recently commissioned our own series of custom rudder designs from Clements

Engineering, these new larger rudder design cast in in N.A.B. with a more

streamlined profile significantly improving handling, directional stability in

rough weather and reduced turning circle. Hypro Marine supplied a powerful

power steering system, now with hydraulic power provided via an engine mounted

170cc pump. This, combined with the larger rudders provides much faster steering

response, with light steering effort and only 4 turns lock to lock. Also

maintenance costs are much reduced as there are no bushes to wear out as in the

electro hydraulic system.